The Art of Making Paper

Paper has so many uses. Writing paper, printing paper, crafting paper, poster paper, paper cups, paper plates, toilet paper, paper straws, and so much more! Whether or not we realize it, we are likely using some form of paper each day. Paper is a truly transformative medium, and it starts in the forest.

However, while much of the paper in the world is made from trees, not all is! Today, we are seeing paper be made from many sources. Some papers are made from bamboo, rice, sawdust, and more. Many domestic manufacturers start with something as simple as woodchips.

The end use of the product helps determine the optimal “chip mix”. In traditional papermaking, stiffness is added by using “hardwoods” like maple and birch. “Softwoods” like pine add strength; they’re also the most commonly used in North America.

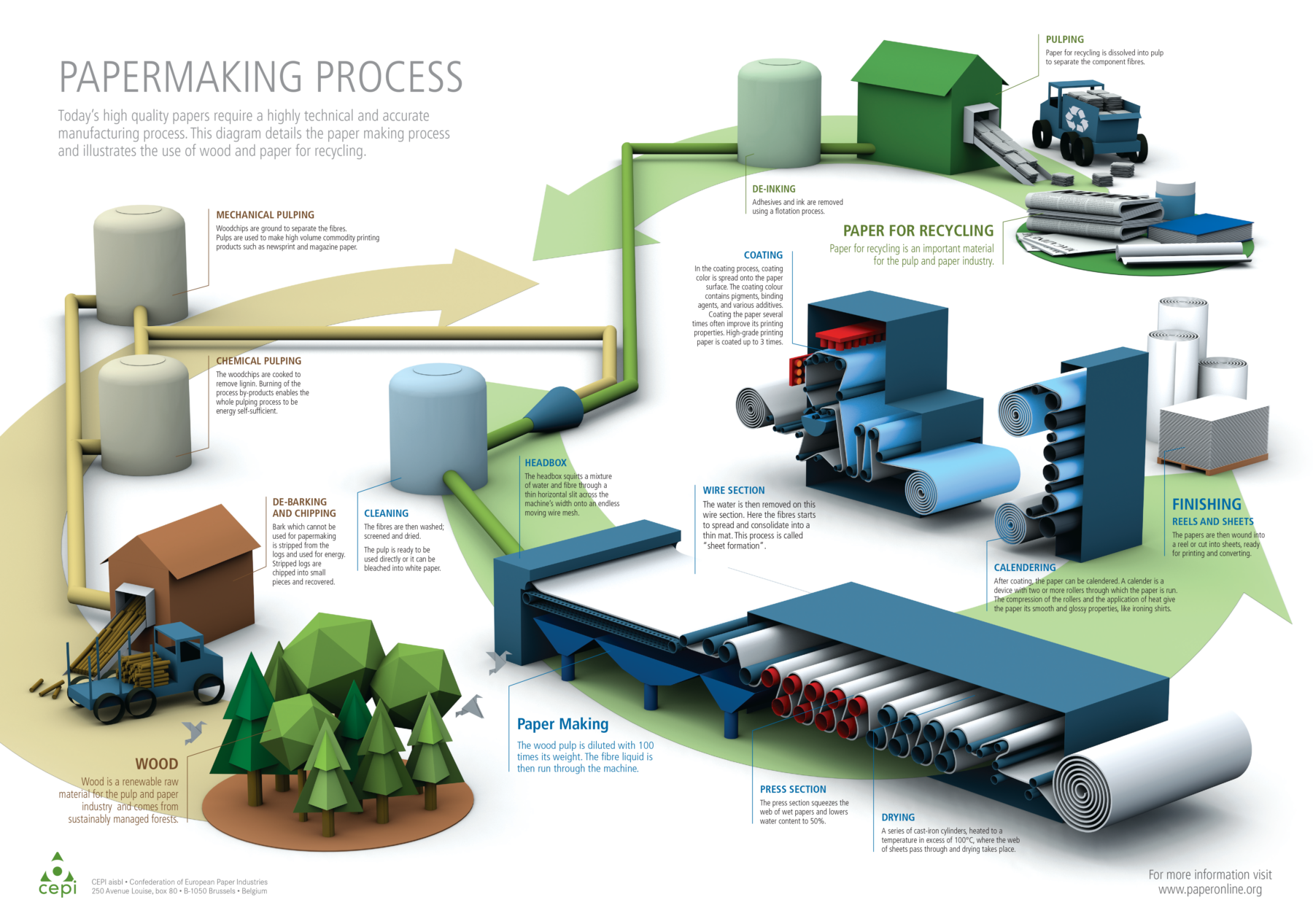

Let’s take a step by step look into the paper making process and how we go from woodchips to a white sheet ready for use. The first step is the pulping process.

Wood is held together with “lignin”. Paper manufacturers remove the lignin from it, and the wood falls apart into a mushy consistency. The removal process is completed by cooking the lignin under high pressure, in the presence of sodium hydroxide and sulfide liquor. See what the pulp looks like at this step below:

Wood pulp in the lignin stripping process.

Fun fact: Lignin is also a biofuel that can be used to generate power. Many modern pulp mills produce more energy than they consume – providing electricity to the local residences and businesses.

Next, paper mills will wash the pulp, screen it for quality, and then bleach it. They will continue cooking and bleaching until the material fits its intended end use in color and function. This lump may fit the bill for certain types of paper, or it could be used for another purpose, like a paper shopping bag.

Wood pulp completely stripped of lignin.

This pulp has been completely stripped of its lignin. For many manufacturers and markets, bright white is the goal. This product is ready for the next step in the paper making process.

Pulp can also be refined into “fluff pulp” for other uses like absorbent personal products such diapers or feminine hygiene pads.

Paper machines can be monsters. In some cases, four times the size of an olympic swimming pool, producing reels of paper 280 inches wide. This is because paper machines are designed with removing water in mind. The bleached pulp is mixed with water, creating a mushy material. This pulp mass is inserted into the machine, then squirted through a horizontal slit over a moving wire mesh to remove excess water. The mesh is moving at around 55mph during this process. As water falls through the screen, the fibers begin to tangle and align creating the foundation of a sheet of paper.

After the sheet is formed, the paper is then dried at high temperatures by running it over large cast iron cylinders. Then, it’s ready to move on to the finishing portion of the process!

Fun fact: The word “paper” derives from papyrus – a plant that Ancient Egyptians used as a writing surface. Thin strips of the root of the plant were layered together to create the writing surface. The earliest evidence of actual papermaking dates back to 200 BCE in China.

Jumbo rolls of paper at Paris Corporation

Jumbo rolls are converted into sheets at Paris Corporation.

The final step is to finish the paper to fit its end use. Some papers will end up rougher or smoother in the end depending on its use. Some types are finished with regular printing in mind (copy and multipurpose paper), while an inkjet printer paper may have a coating that is meant to help ink dry faster and prevent smearing.

There are lots of different processes that go on to make your paper perfect for its intended use! Whatever that may be, the finished product is usually rolled in large “Jumbo Rolls” and converted (or cut) into the appropriate size for use.

After the paper is cut, it’s packaged into cartons or ream wraps and then shipped out for use! Paris Corporation is a paper converter that takes these jumbo rolls of all types and makes them into the awesome PrintWorks, Elementree, and DocuGard paper products that we know and love!

To learn more about paper and how it’s made, check out these resources:

Follow us @printworksdiy on social media for more craft inspiration, and visit our Store to check out the rest of our product line.